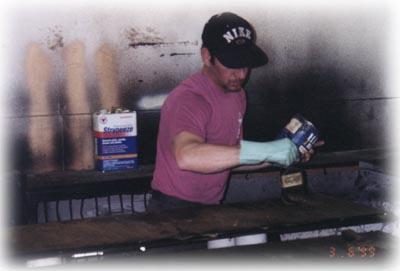

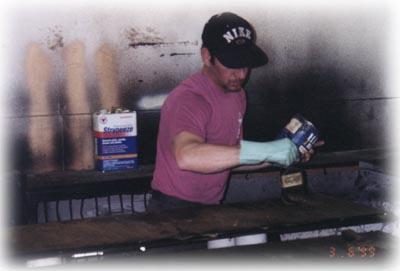

Joey, paying careful attention to detail while stripping off a finish. |

|

| New Pianos | |

| Natural & Ebony Finishes | |

| Rebuilding | |

| Reference Letters | |

John Koelle (847) 336-5919 |

|

Piano Refinishing |

|

John Koelle has been refinishing Steinway and other fine pianos in the Chicago area for the past 24 years. Ebony (black) and natural woods are available and we can usually match any color sample. The following links will give you a little more detail about the process.

|

||||||||

Joey, paying careful attention to detail while stripping off a finish. |

|

| New Pianos | |

| Natural & Ebony Finishes | |

| Rebuilding | |

| Reference Letters | |

|

It is extremely important to make the distinction between hand stripping and dipping. Hand stripping, as the name suggests, is performed by hand. Several coats of professional strength stripper are applied to the piano's veneer with a brush and then removed with a hand-held scraper. Once the old lacquer has been removed, the wood is washed--again, by hand--with a professional strength thinner and steel wool. "Dipping" is a process in which the piano's various parts are literally--and repeatedly--dipped into a vat of stripper until the old lacquer falls off. The greatest risk involved in "dipping" is the stripper's potential to penetrate and ultimately damage the wood itself. Although it is certainly more time-consuming, hand stripping is by far the best method if one is to preserve the original state of the wood. Hand Sanding and Staining Once the stripping has been completed, the piano is then sanded by hand with 120-grit sandpaper. The type of finish, i.e., either ebony or natural determines the shade to which the veneer is sanded. A piano receiving a natural finish is always sanded to an even and uniform color. The next step is the application of a high quality, paste wood filler. The purpose of this procedure is twofold: first, in the case of natural finishes, the filler adds color to the veneer-- those customers receiving a natural finish are requested to approve a color sample before any further work is performed; second, the paste actually fills in the pores of the piano's wood. Sealing and Priming At this point, five coats of sealer (or in the case of ebonies, black primer) are applied with a spray gun. This is then left to dry for four to five days. Application of Lacquer Once the primer has been given sufficient time to dry, it is scuffed down with 180-grit sandpaper and six coats of high gloss black lacquer are applied. After another four to five days, the piano is scuffed--once again with 180-grit sandpaper--and the final six coats of lacquer are applied. The finish is then given approximately ten days to cure before the final stage, hand rubbing. Hand Rubbing Hand rubbing (wet sanding), is the final stage of the piano's cosmetic journey. This is the most critical period of the refinishing job, because any mistakes--for example, sanding through the lacquer to primer, or worse, bare wood--could take several days or weeks to remedy.In a mechanical sense, rubbing is very similar to that of standard sanding or scuffing. Like scuffing, the objective is to remove all pores from the piano's surface. The primary difference however, is that rubbing requires the use of a much higher grade of sandpaper, typically 400-grit, as well as water and a professional wool-wax to act as lubricants. Once the sanding has been completed, each piece is rubbed out with wet steel wool to give the finish a deep, satin sheen. |

| Main Page | Moving | Tuning | |

| New Pianos | Refinishing | Natural & Ebony Finishes | |

| Rebuilding | |||

|

Contact

John Koelle |

|||

All content ŠJohn Koelle,

1999 - 2007

Site design and hosting: www.pin.ca